Label is primarily information appended to a product or its

packaging giving the brand name, information on the product, its usage, safety

instructions, manufacturer’s details, statutory information, prices and now bar

codes that provide a system for track & trace, price information, inventory

control and logistic support. How the label or the required information has

been attached to the product has varied over the ages. The earliest form of

labeling was done by etching, embossing or stamping brands and information

directly on glass or metal containers. Labels have been in use for hundreds of

years but labels as we know today have evolved largely after the 17th

century. Printing originated in China in the 11th century and was further

developed in Korea in the 12th century but a wooden block printing press

for mass printing was invented by a German Johannes Gutenberg in

the mid-15th century. It was only in the

earlier part of 18th century that printed paper labels surfaced as a

possibility but since adhesives to affix these labels were not available, their

usage started later. By then lithography had developed, so directly metal

printed containers started being used for packing and canning. Many products

are still packed with modern canning processes using metal cans printed with

the lithographic printing process. It was only in the 19th century

that printed paper based labels started being used for labeling and packaging

using natural gum based adhesive to stick the paper labels to glass, metal or

paper based containers and packaging. These labels in an evolving label

scenario are now referred to as Wet Glue Labels.

With increasing levels of literacy,

growing population and growth of packaged products, mass production in

factories has become an imperative. New glass, paper, metal and plastic based

packages are being developed to catch the eye of demanding consumers. The

aesthetics are enhanced by affixing colourful and attractive labels. Faster

labeling and packaging methods evolved as also the need to have highly

decorated labels to service the need of consumers. Driven by this demand labels

have evolved into different tangents. Diverse and technical labeling

technologies have emerged. Listed below are some of the prominent technologies

that labels have presently evolved into;

- Pre

printed labels on metal container

- Wet

Glue Labels

- Self

Adhesive Labels

- Self

adhesive Liner less Labels

- Heat Transfer Labels

- Direct

on product screen printed labels

- Contact

printing and stenciling

- Laser engraved labels

- Metal

anodized labels

- Shrink

Sleeves

- In Mould Label

- Digital: Direct on product Labels

- 3D Printed labels

Pre printed labels on

metal containers: Metal

containers or cans are made from tin plate (steel

covered in a thin tin layer)

or of Aluminum and steel coated with a lacquer. The labeling is done in any of

the three different ways listed below;

- Metal

tinplate sheets are printed by offset process and then converted into

containers.

- Preformed

round metal containers are printed using a curved surface printing machine.

Each color of ink is placed on a different (plastic letterpress) plate, and

then transferred to a single rubber blanket which re-transfers the inked image

to a can allowing all colors to be printed at a time followed by ink curing and

varnishing.

- Preprinted

labels of paper, film or foil are laminated to preformed cans. These labels can

be printed by, flexo, offset, gravure, or digital printing processes. These can

be highly decorated on high end hybrid narrow web presses having advanced

finishing capabilities. These labels can be applied as full wrap around labels

or part labels with the balance surface left coated to show a metallic lustrous

effect.

Wet Glue Labels: These labels are also referred to as

glue applied labels. These formed the mainstay

of product labeling until well

into the middle of last century. Labels initially printed on letter press

machines and later on offset presses, were gummed manually and applied to the

bottles or containers. In 1880 De La Rue

came up with a machine for gumming labels but this had a problem as paper

labels would curl as soon as they would come out with gum applied on it making

it difficult to handle. From my personal

experience I can cite example of how our company adapted to manual gumming of

labels. Our parent company was established in 1939 to produce fountain pen inks

and office adhesive that were packed in glass bottles. To achieve optimum level

of production we devised an interesting method of applying glue and labeling.

Those days the final packing was done in wooden cases, corrugated boxes came

much later. We took a wooden crate and turned it upside down, spread a full

roll of surgical cotton on it and then covered it with a thick cotton cloth

that was tightly fixed by nailing it all around. This was then dipped into

water overnight with its face downwards. In the morning we would squeeze out

the water and our gumming pad was ready. A thin solution in water of natural gum

(Gum Acacia) that grows on trees was applied on the pad and then labels spread

on it. We would have the unlabelled bottles on one side of this pad and with a

little gum on the finger, which made it a little tacky, lift the evenly gummed label

off the pad and place it on the bottle without any curl and put on the other

side for further packaging. Subsequently

with development of high solid faster drying Dextrin based adhesive automatic

machines to apply gum and dispense labels to the bottles were developed. This

made large scale production on automated production lines possible.

Direct on product

screen printed labels: Screen printing saw growth in the Indian label scenario in the middle of

last century. A lot of consumer product that shifted from glass to plastic

packaging also opted for screen printed containers. However this did not last

for many years as self adhesive labels with the high end decoration they

offered soon became the preferred option. However screen printing on container

is still in use but has limited application.

Self Adhesive Labels: In 1935 “Ray Stanton Avery”

developed the self adhesive label also referred

to as Sticker or Pressure

Sensitive Label. This label revolutionized the way how the world branded and

labeled their products. The label basically consists of a face stock which

could be paper film or foil, coated with a tacky non drying adhesive and

protected with a backing also referred to as release liner. The label after

printing and die cutting just needs to be lifted off the release liner and

placed on the product achieving instant bond on applying pressure, unlike the

wet glue labels that need drying after application otherwise they would shift

and look bad. The self adhesive label industry has over the years evolved to

offer a diverse range of labels catering to various industries and applications

that include fmcg products, lubricants, cosmetics, food, Pharmaceuticals, variable information, logistics, brand

protection, etc. In the initial years these labels were printed and die-cut on slow

flat bed letterpress presses and with time they are now printed on high speed

flexo rotary or combination label presses with capability to decorate and

finish the labels in line in a single pass delivering finished labels at the

end of the line. These labels are used on high speed label dispensing machines

adding to production volumes for end user.

Self adhesive Liner

less Labels: Self

adhesive labels as described above have an issue as regards the

environment.

The release liner and waste matrix after die cutting is not generally recyclable,

though efforts are being made in this direction. This waste goes either to the

landfills or is incinerated impacting the environment adversely in both cases. Moreover

if the liner can be done away with while converting this type of label, it will

amount to cost saving and become eco friendly. Considerable amount of work has

been done in this direction and various options are now available. The simplest

one being to make a tape like product printed, and siliconised on one side and

adhesive coated on the reverse and self wound. However these labels that can be

cut with sharp corners, cannot be die cut and dispensed in regular labeling

equipment. Many European and US based food companies are already using such liner

less labels. There is development being done to overcome the challenges of die-cutting

complex shapes and dispensing cost effectively.

Heat Transfer Labels: PET film that is precoated with

special release lacquer is reverse printed by flexo, offset or gravure to form

labels in roll form. The image is transferred onto the container or product

using heat and pressure. The labels are a composition of inks and lacquers

selected so as to perform to customer’s specific needs. On transfer these

labels are just the image and no substrate is transferred. Many years ago Mumbai

headquartered Paper Products Limited (now Huhtamaki PPL) commissioned this

technology known as “Therimage” with help of Avery Dennison. Later with self

adhesive label emerging as very decorative in presentation, this technology

lost its popularity. In recent times it has resurfaced. It is extensively being

used by the pen industry.It is now being extended to garments and other product segments.

Contact printing and

stenciling: In

present times even the corrugated shipper cartons bear self

adhesive labels

needed for identification, inventory control and logistic requirements. In

earlier days as I mentioned, wooden cases were used as shipper cartons. People

would write on them using marker pens but when need for aesthetics became

important stencils were made of tin plate. They were placed on the wooden cases

and ink brushed over them to imprint the required information. Later when

corrugated boxes started to be used for final packaging, roller contact

printers with changeable rubber types and foam ink rolls were available to

print the information that could be changed by changing the type faces as per

need. Once corrugated cartons replaced the bulk of outer packaging, these

cartons started to be printed and self adhesive labels applied, if needed.

Stenciling is still used where wooden crates are required for final packaging.

Laser engraved labels: Steel or other metal auto components,

like bearings need to be branded, they cannot be labeled with paper or film

labels. Only the secondary packaging can be branded, this can amount to

duplication and counterfeits. For this reason laser engraved branding is

preferred. A laser beam which

is a very small, focused point of laser power effectively superheats a tiny

point of a surface and removes part of the surface, creating a permanent

engraving. This beam of light is controlled and moved to create a brand name or

permanent design.

Metal anodized labels: These labels are used in

applications where permanent product identification

is critical such as

equipment nameplates, signage, safety/warning plates, machine control panels,

etc. Abrasion and corrosion resistance anodized aluminum labels are produced by

chemical etching on photo sensitive anodized Aluminum. These are mostly riveted

on to the equipment or panels as they are required to last most of the life

time of the equipment.

Shrink Sleeves: Shrink sleeves offer 360 degrees

space for decoration and product information. They are made of either of these

materials; Polyester, PE, PVC or PP. Pre printed film is welded to form a tube,

cut to desired size of the bottle or container and applied over it. It is then

exposed to a heat gun or passed through a heated shrink tunnel for the tube to

shrink and attain the form of the bottle or container providing all around

decoration. Shrink sleeve labels originated in 1965 and invented by Fuji Carpentry

shop that were later named as Fuji Seal. The actual large scale usage of these

sleeve labels commenced in the mid 1980s. According to Suresh Gupta Chairman of

Huhtamaki PPL, shrink sleeves were brought to the Indian market in 1991 when

Paper Products Limited (now Huhtamaki PPL), set up the plant with help from

Fuji Film to make these in India. This segment continues to register a steady

growth rate. Global growth is 6-7% but in India it is slightly more, given the

size of the market. In India these are largely printed on gravure printing

presses. However in recent times, in an effort to cater to short run customers

who maybe large customers doing special editions or small and medium

enterprises, printing is also being done on flexo presses and in some cases on

digital label presses.

In Mould Labels: Paper or film printed labels (mostly

filmic) are placed inside the moulds during

the molding process. After placing

the label, molten plastic is injected into the mould. On cooling the label is

fused with the resin, takes the shape of the so molded container and becomes an

integral part of it. The labels referred to as IML can be printed and decorated

by any of the processes i.e. Offset, Flexo Gravure or digital. The end result

is a highly decorated container. These IML applied containers are used for Ice

cream, butter, paints, food packaging, etc. According to research firm

MarketsandMarkets, the global in-mold label (IML) market is projected to grow

from

$2.58 Billion in 2015 to

$3.23 Billion by 2020, at an estimated CAGR of 4.54%. It is the fastest

growing segment amongst the various label segments.

Digital, direct on

product Labels: Digital

printing has made its presence in all variants of label

printing and

converting. From wet glue to self adhesive and in mould labels, digital

printing is making inroads everywhere. Some years ago when I was interviewing

Helmut Schreiner, the former Chairman of

Schreiner Group, I asked him, “What do

you see as the biggest threat to self adhesive label industry?” He became

pensive and after deep thinking said, “It will be digital printing direct on

the product”! It makes a lot of sense as we see the market slowly evolving in

that direction. This will open up a whole lot of opportunities for the brand

owners. No paper, no silicone, no adhesive, no dies, no tooling and yet the

option to indulge in personalization and creativity! According to

AlexanderWatson Associates, “It may, indeed, be a disruptive technology”. Direct to

digital has been around for some time printing on textiles and ceramics. It is

commonplace to see digitally printed fabrics and ceramic tiles. It has started

to make inroads into the consumer product market and we need to wait and watch where

it leads to.

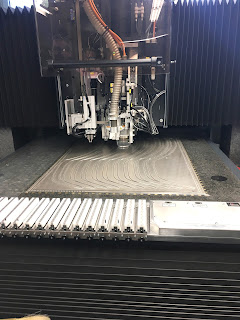

3D Printed labels: This is another technology which may

see computer controlled 3D characters and images on products and labels. It

will make the imagination go wild on what all can be created. It is a process

in which layers of material are formed under computer control process to create

an object that can be of almost any shape formed by deposits of binder material

onto a powder bed with inkjet printer heads layer by layer.

The evolution of labels has created a whole bouquet of

technologies which still keep coming up in new avatars. No one technology can become the predominant one for label

production. With labels diversifying into different tangents, label printers

need to select the way forward so as to stay innovative and ahead of time. It

is surely time to emerge out of the crowd and create a separate visible entity.

Written Exclusively for Label and Narrow Web magazine USA by Harveer Sahni, Chairman Weldon Celloplast Limited,

New Delhi November 2017. The article may not be reproduced without the magazine's or the author's permission.